Machine Vision on Assembly Line: the Roboworker Super Robot Feeder

Machinery | Packaging & Logistics | Robotics | Classification | Matching | Measuring

Since more than 15 years, ROBOWORKER Automation GmbH (Weingarten, Germany) is specialized in developing and producing systems for automatic handling, assembly and checking of workpieces as well as robot-aided loading and unloading of production machines. The company now has developed a robot feeder system that has automated the handling, inspection and packaging of indexable inserts.

To properly inspect and then pack vending boxes of indexable inserts, stacks of trays are automatically unloaded row by row from an RL 20 linear robot machine manufactured by ROBOWORKER Automation GmbH (Weingarten, Germany). Every two seconds the conveyor is forwarded one part. However, because the demands of the manufacturer required a greater throughput of 120.000 parts per day, four separate conveyors are loaded in parallel from the same depalletizing machine. This results in a throughput of approximately one part every 0,5 seconds. Parts placed on all four conveyor belts approximately 20 mm apart (depending on the number of rows of the trays) by the depalletizer are then moved under a machine vision system where they are inspected for position, rotation and geometric properties

as incircle, outer circle, hole diameter and included angle. As the

parts move under the station, they are backlit so that the system

can more easily determine the orientation of each part.

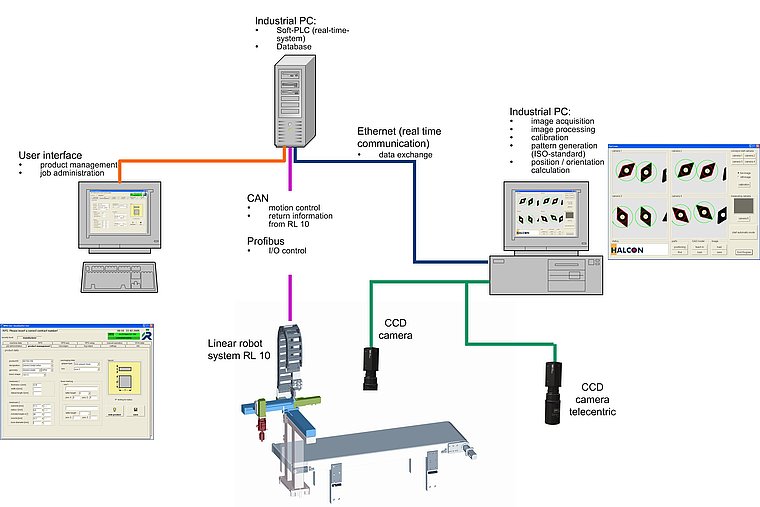

To digitize images of the parts, several monochrome cameras are interfaced to a PC. The images are analyzed using the HALCON machine vision library from MVTec Software GmbH. By using the pattern matching tool within HALCON, the position and orientation of each part can be extracted from the image even if parts are rotated or partly occluded. The software uses HALCON’s contour based pattern matching and locates objects based on their shape. This leads to a reliable detection even under changing lighting conditions.

Dimensions such as incircle, outer circle and hole diameter of each part are measured with a precision of 50 µm. When measuring the cutting edge radius and the part angle, subpixel accurate edge extraction algorithms are used. These procedures work reliably also under rough production conditions.

The system checks also, if a part is visible in the camera, detects wrong parts and can measure the dirt on the conveyor belt. Once the dimensions have been calculated, they are compared with the dimensional limits and tolerances of known good parts from an ISO-standard database. In this way, the system determines whether the parts can be transferred to the next inspection station or have to be discharged.

After the software has determined both the x-y position and orientation of the indexable inserts, the coordinates of each part are transmitted from the PC to a programmable logic controller. With the help of HALCON's 3D camera calibration, the system establishes a relationship between each pixel and the robot coordinates. The determined position and orientation data can be handed over directly to the robot. Tilt of the camera, distortions of the lens as well as not right-angled robot coordinates are corrected. The height of the indexable insert is also considered during the measurements.

"In the case of this machine, the image processing software we used for many earlier projects was overtaxed regarding to the demand of complex packing and measurements", says Michael Giray, managing director at Roboworker. "Then we found HALCON and noticed that this software library offers exactly what we were looking for: flexibility, parameterizable programming and robustness."

Author: Dr. Lutz Kreutzer

All product names, trademarks and images of the products/trademarks are copyright by their holders. All rights reserved.