Vision System Inspects X-ray Dosimeter Badges – Helmholtz-Zentrum

Medical Supplies & Pharmaceutical | Bar Code & Data Code Reading | Blob Analysis | Calibration | Classification | Filtering | Matching | Measuring | OCR & OCV | Subpixel

In Germany, the inspection of x-ray dosimeters worn by people who may be exposed to radiation is a governmental responsibility. Only a handful of institutions are qualified to perform such tasks. One of which, the Helmholtz-Zentrum (Munich, Germany) is responsible for the analysis of approximately 120,000 film badge dosimeters a month.

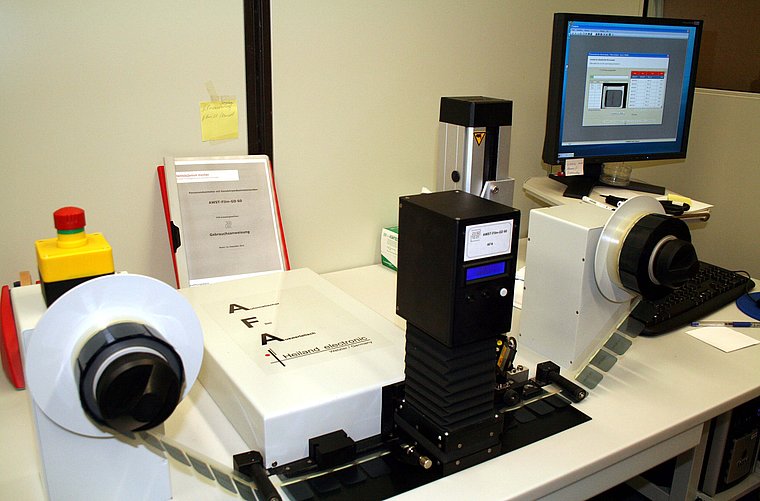

Previously these 120,000 film badges were evaluated manually. To speed this inspection and increase reliability, the Helmholtz-Zentrum has developed a machine-vision system to automatically inspect these films. The film from each dosimeter badge is first mounted on a plastic adhesive foil, which is wound into a coil. This coil is then mounted on the vision system so that each film element can be inspected automatically (see figure). To analyze each film, a DX4 285 FireWire camera from Kappa optronics (Gleichen, Germany) is mounted on a bellows stage above the film reel. Data from this camera is then transferred to a PC and processed using HALCON 9.0 from MVTec Software (Munich, Germany). Resulting high-dynamic-range images are then displayed using an ATIFire GL V3600 graphic board from AMD (Sunnyvale, CA, USA) on a FlexScan MX 190 S display from Eizo (Ishikawa, Japan). Before the optical density of the film is measured, its presence and orientation must be determined. As each film moves under the camera system’s field of view, this presence and orientation task is computed using HALCON’s shape-based matching algorithm. Both the camera and a densitometer are used to measure the optical density of the film.

The densitometer measures the brightness at each of seven points on the film in high precision and is used to calibrate the camera measurement for every film image. To increase the dynamic range of the gray-level image of the film, two images with different exposure times are computed and combined into a high-dynamic-range image. Because the background lighting is not homogenous, shading correction is performed to eliminate any lighting variation. Any lens vignetting and variations caused by pixel-to-pixel sensitivity variation is eliminated by flat-field correction. The optical density is converted into a photon dose using a linear algebraic function to calculate the x-ray dose to which the film was exposed.

Every film reading must be correlated with the unique specimen number associated with each badge. Since these numbers are deposited onto the film material, approximately 10,000 characters needed to be trained and saved to an OCR database using HALCON. After the film is identified, the system must also detect which type of dosimeter cassette has been used to house the film. Since each cassette uses a different x-ray filter, the shadow cast on the film can be either rectangular or round. Thus, a grayscale analysis of these shadows can be used to detect the differences between the different types of cassettes that were used to house the film. To pinpoint the specific causes of x-ray exposure, the system is also programmed to detect whether any potential exposure is caused by errors in film developing or x-ray contamination. If the imaging system detects contamination events, these are then reported manually.

Author: Andy Wilson

Article kindly provided by Vision Systems Design. All product names, trademarks and images of the products/trademarks are copyright by their holders. All rights reserved.