Everything at a glance from the cloud: Smart Factory in the automotive industry

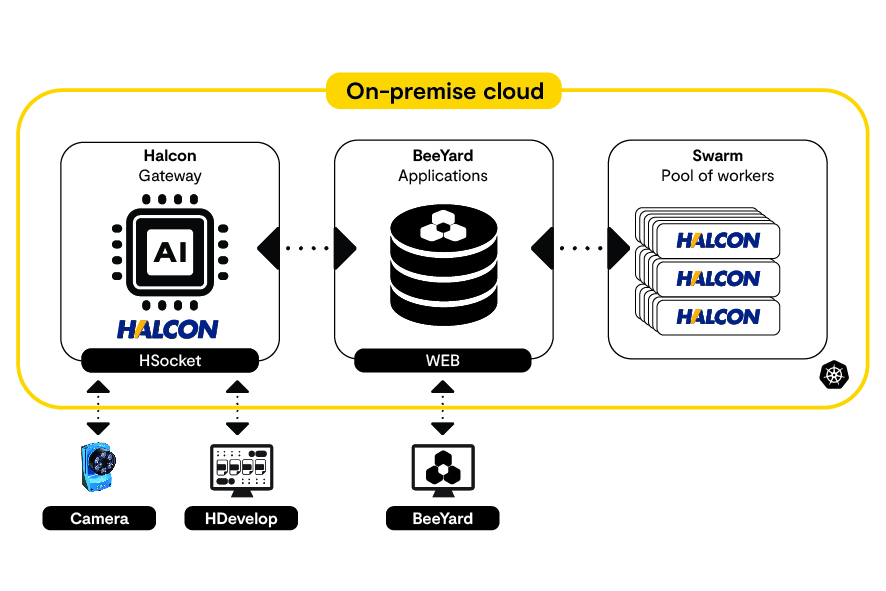

AutomotiveDataVision and MVTec have developed a machine learning platform combining a cloud solution with machine vision to increase efficiency in development and production. The basis of the platform is an application that SICK AG has successfully implemented at ŠKODA AUTO in the Czech Republic.

Smart Factory in the automotive industry

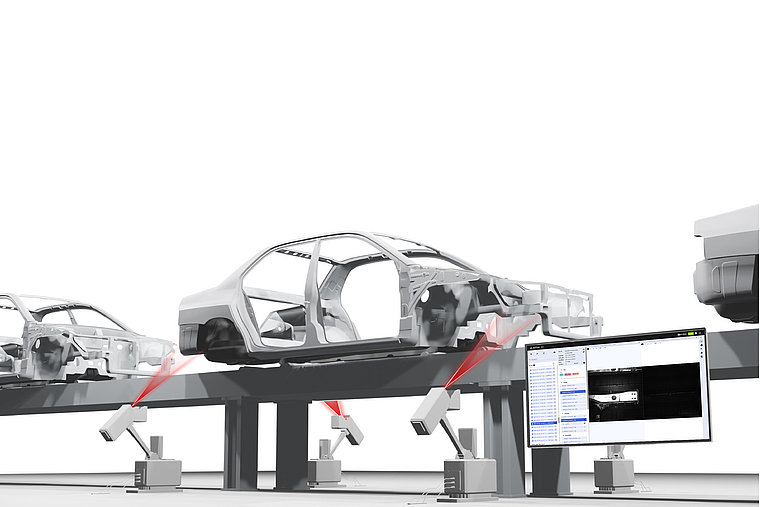

In ŠKODA AUTO's production, car bodies were previously lowered mechanically onto pins and the robots were aligned statically. To make the Smart Factory more flexible, energy-efficient, resource-saving, and cost-effective, SICK has implemented a fully automated application for position determination for ŠKODA AUTO in the Czech Republic. The company DataVision s.r.o. has developed BeeYard with the support of MVTec Software GmbH. The cloud-based machine learning and data management platform combines the advantages of industrial image processing (machine vision) with those of the cloud. Instead of mechanical lowering and lifting, the body at ŠKODA AUTO is now simply stopped at the raw position. Here, a Body Positioning System (BPS) records the exact position of each body approaching the welding cell.

Position detection with machine vision instead of mechanical lifting

The heart of the application is the BPS. The machine vision-based solution is used directly on the production lines in ŠKODA's welding shops. Each welding cell has four measurement modules that together determine the exact 3D position of the car body in the production line. One of them is used for redundancy. With the machine vision software MVTec HALCON, the position of the car body can be reliably determined, enabling the welding robots to achieve an accuracy of +/- 1 mm during spot welding. The new system thus not only ensures process-safe adaptive robot control, but also a connected production in which process-relevant data is collected. The measured values are stored and used to improve the algorithms and increase system performance. This enables, for example, positioning accuracy of almost 100 percent. ŠKODA AUTO also uses the collected data to trace the production processes and to check system stability.

Improved algorithms thanks to Big Data in the cloud

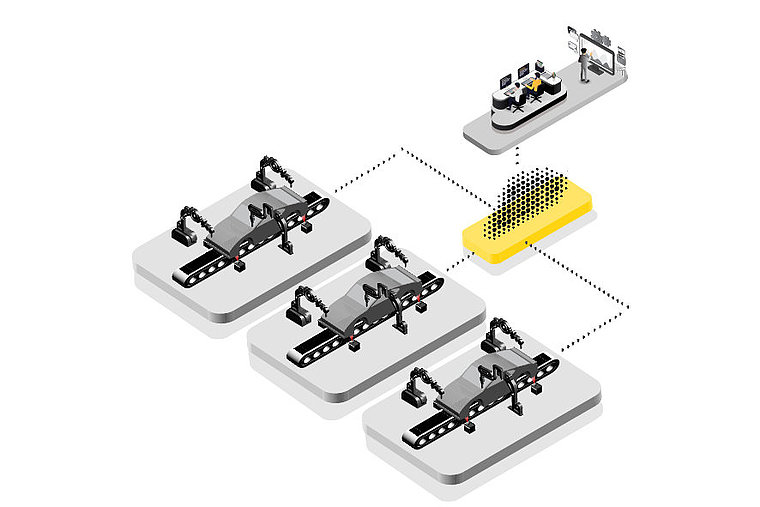

The BPS at ŠKODA AUTO is based on algorithms developed with the machine vision software MVTec HALCON. The BPS continuously measures car bodies in the production line and stores the measured data. Thus, in the event of a modification in production, for example for a new body type, the interactive BPS web interface can easily process this change. If a new feature needs to be added, BeeYard provides the right tools. This enables the performance of the new algorithm to be evaluated its performance to be demonstrated to ŠKODA before it is used in production. With this approach, possible errors of the new algorithm are virtually eliminated thanks to validation against a data set of more than one million images from the production history. This also allows for improved overall algorithm performance and stable releases of new versions. The BeeYard platform allows data from different stations to be merged into one data set. That way, it is possible to test the algorithms not only in individual welding cells, but also across sites, even from different production plants. This deep insight into all production data enables the optimization of production, algorithms, and equipment maintenance.

Advantage of digital solutions for Smart Factory in the automotive industry

In the meantime, the system has been in operation for two years. "The application has met our goals and requirements in several respects. First, there are the goals of profitability, efficiency and, last but not least, climate protection," says Jan Čejka, project coordinator for "Welding Shop Robotizations" at ŠKODA AUTO. Specifically, extremely robust localization rates of nearly 100 percent are achieved, resulting in a five percent reduction in cycle times for individual car bodies. In addition, compared to mechanical solutions, mechanical wear and maintenance are almost eliminated completely, resulting in lower operating costs. Finally, there is a significant reduction in energy consumption, which is associated with an improvement in the CO2 footprint.

Other goals of the project were the steps on the way to the smart factory. "By transforming from a mechanical to a digital solution, we were not only able to achieve improvements, but also realize completely new use cases and significantly optimize production," a pleased Čejka says. The use of intelligent networking of cloud and machine vision increases flexibility, for example by allowing different types of car bodies to be processed on a single production line. Furthermore, there is another point that goes beyond the mere transition from a mechanical to a digital solution: as part of the Industry 4.0 effort, a large amount of data is being collected that can also be used for other purposes. One example is predictive maintenance. Necessary machine maintenance is now detected at an appropriately early stage, which ultimately prevents machine downtime and reduces maintenance costs.

The images of the products/brands are subject to the copyright of DataVision. All rights reserved.