Machine Vision Inspects Biscuits – Machine Vision Technology Ltd.

Food & Beverages | Packaging & Logistics | 3D Vision | Measuring

As imaging software becomes more advanced and the latest 3D imaging tools open the doors to techniques that where not possible before, one of Europe's leading biscuit manufacturers gets an automated vision solution that takes the biscuit.

The Food and Beverage industry has become extremely competitive and consumers continue to expect high quality and presentation. Those who buy a packet of biscuits want consistent size, weight and quality of each single biscuit. The main objective of the biscuit manufacturer is to achieve economic production, be smart with the resources and packaging. They need to react quickly and reliably on disturbances in the production process by means of data and experience from the past. Therefore, process data has to be acquired and stored continuously and must be efficiently accessed on demand. One of Europe's leading biscuit manufacturers approached Machine Vision Technology Ltd. in Leamington Spa, UK to automate the size and the weight control of their biscuits during the production process. In the production line 30 rows of cooked biscuits will pass underneath on a continually moving conveyor that needs to be inspected. Per minute 120 columns with 30 biscuits each must be checked, that is a total of 3600 biscuits per minute.

Two of the biscuits are then combined with a filling and result in a 'sandwich biscuit' in the end. The ultimate aim is to ensure all 'sandwich biscuits' are the same height and weight. A biscuit consists of two 'sides' with a fondant filling (such as chocolate) in between. The customer needs to measure each side of the biscuit to then know how much filling is required to make the 'sandwich biscuit' the correct overall height. Filling is expensive in comparison to biscuit costs so the idea is to minimize how much is used to create a 'sandwich biscuit' of the correct height and weight. The biscuit size is easily controlled by raw ingredient weight and pressures which create the original sheet of dough. As required for the food industry, the system is in stainless steel with the installation up to food industry standards.

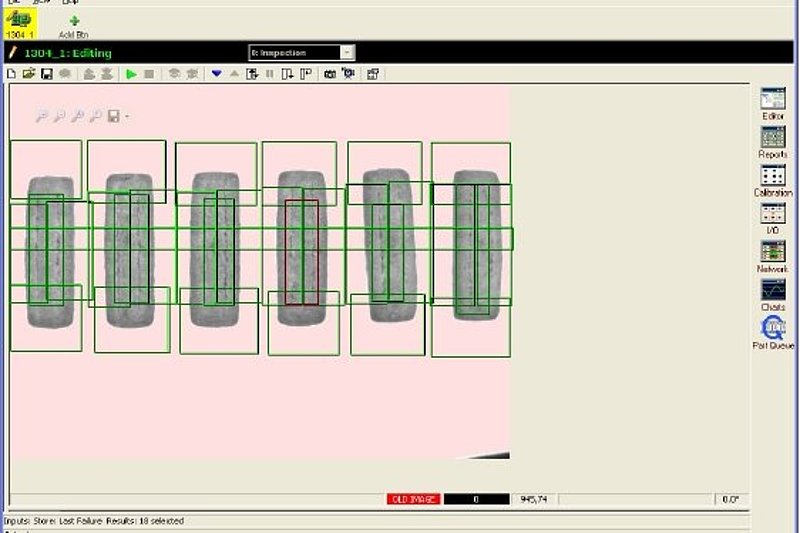

Machine Vision Technology Ltd, approached MultiPix Imaging, a UK vision components supplier for advice on Camera and Image Processing Software selection. The solution consists of three Basler Scout cameras (scA1390) being used to grab images of the biscuits from above and HALCON Imaging Software which will analysis the image to measure the length and width and ascertain if the biscuit is the correct size. A fourth camera, the Basler scA640-120gm is used in partial scan mode for higher frame rates, grabbing a laser line profile of the biscuit HALCON Imaging Software constructs a 3D image and obtains accurate height measurements. Using this procedure, accuracies of ± 0.17 mm regarding the length measurement, ± 0.17 mm regarding the width measurement and ± 0.17 mm regarding the thickness can be achieved.

The custom front end of the software incorporates an average size display for the measurement over the last 100 rows. These statistics are stored against time and date for four years to satisfy customer traceability demands. The operator can easily select from a drop down menu for product changeover. All this information is available on a duplicate screen display 100 meters away for monitoring by an engineer. Thus, GigE is the ideal interface for this application.

Machine Vision Technology is an MVTec Certified Integration Partner. All product names, trademarks and images of the products/trademarks are copyright by their holders. All rights reserved.