Measuring

What used to be done with a gauge is now done by industrial image processing: measuring distances, thicknesses, areas or widths – in 2D as well as in 3D. The results are more detailed, precise and accurate than could ever be achieved manually.

Machine vision systems are called on here in a number of areas:

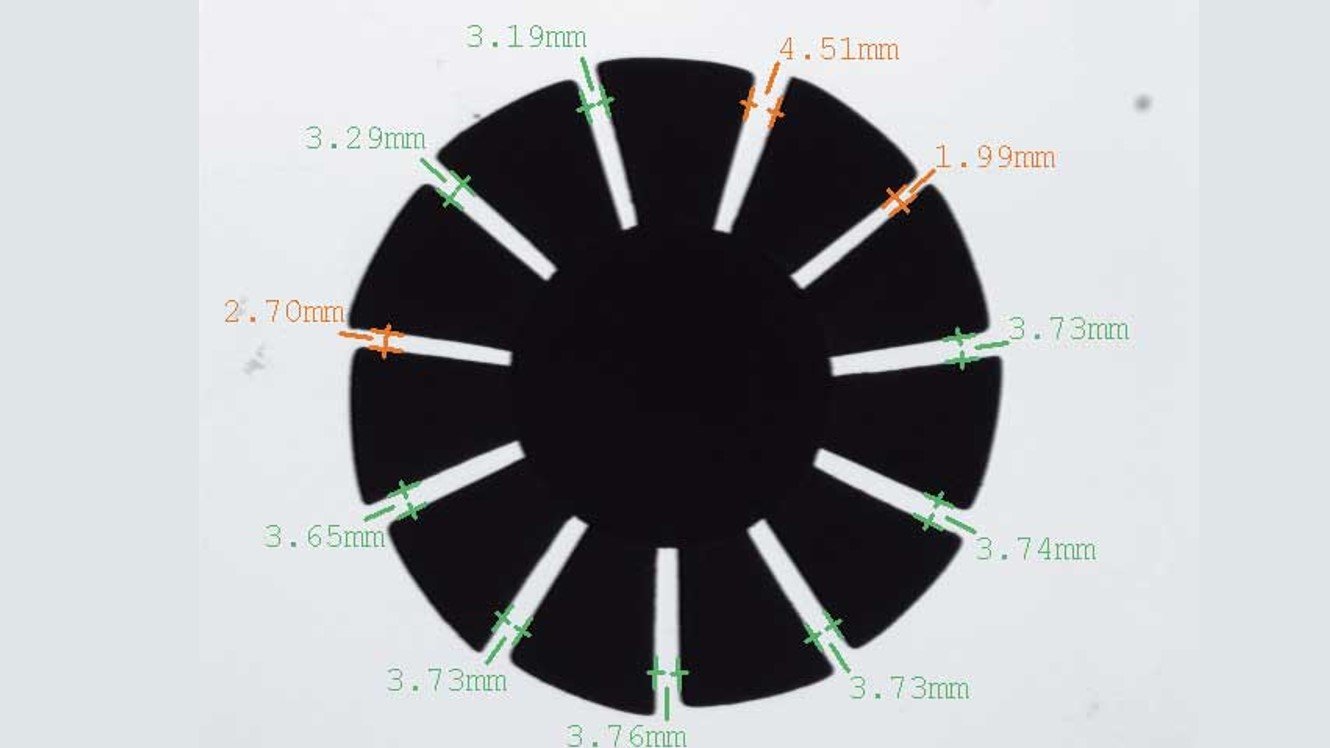

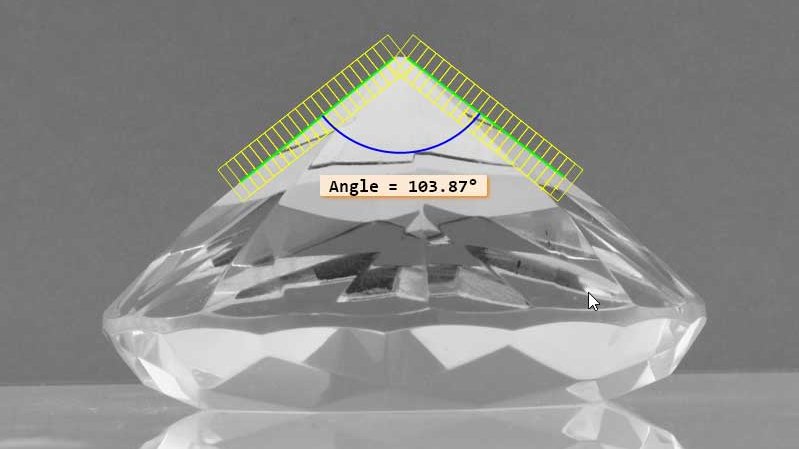

- Measure dimensions like length, width, or distances as well as angles or radii of manufactured parts with high accuracy

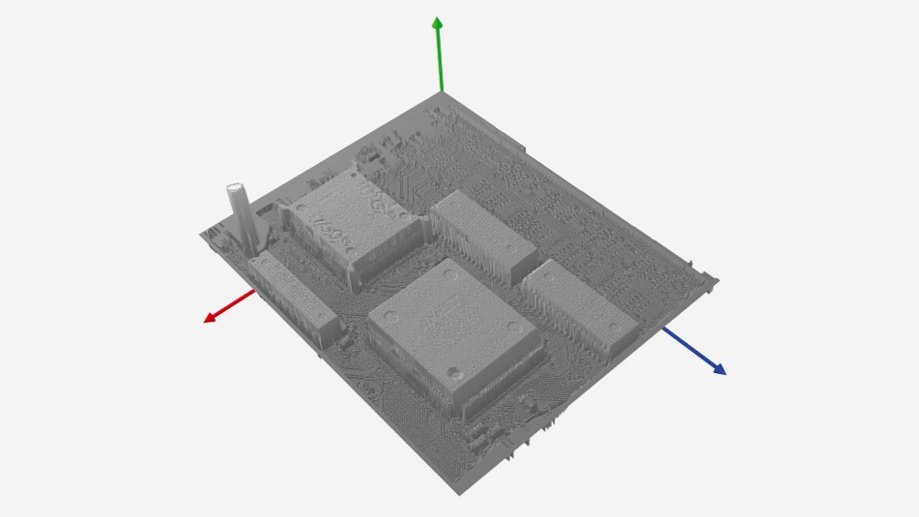

- Perform 3D measurements to also acquire information about a good’s height or volume

Very specific application examples are:

- Checking the dimensional accuracy of milled components in the metal industry

- Measuring the radii of ball bearings

- Measuring a plant’s attributes like height, leaf area and stem diameter

- Checking the dimensions of a smartphone’s charging port

- Measuring the size of solder joints on PCBs

- Verifying the height difference between a laptop’s trackpad and case

Read more about the technologies, you will find in your software products to help you with your measuring applications:

Measuring technologies

Read more about how machine vision could be helpful in your industry or take a look at our customers success stories to find specific examples of the applications.