Quality inspection

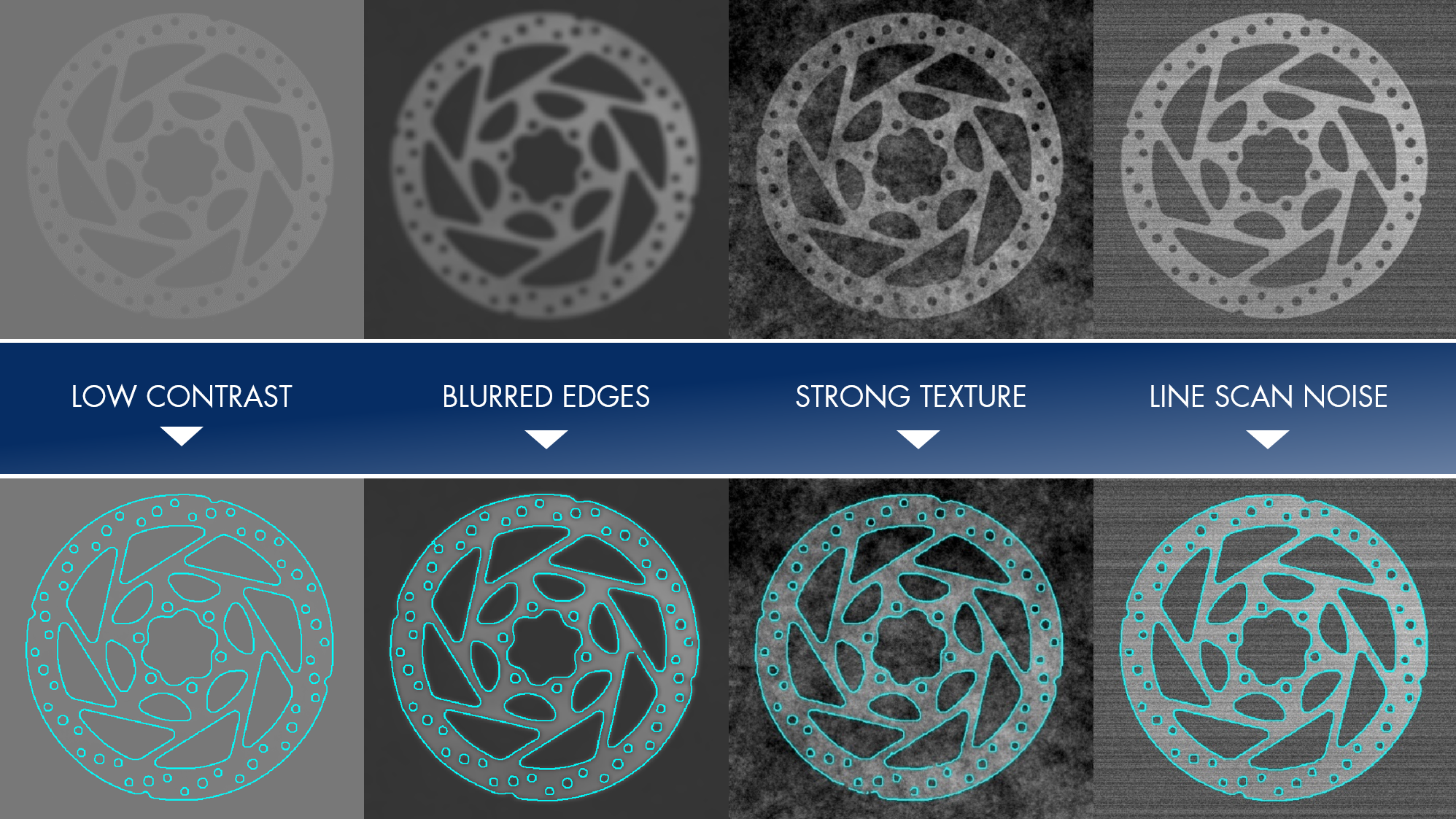

In virtually every production scenario, there is at least one step in which it is verified that the product meets certain quality standards. Today’s highly automated production environments, heavily rely on machine vision to accomplish this task, because it offers numerous advantages over the manual inspection: Machine-vision-based inspection is much faster, the results are objective and reproducible, and the quality of the inspection does not run the risk of deteriorating due to, for example, fatigue or because of the monotony of the task.

Machine vision systems are called on here in a number of areas:

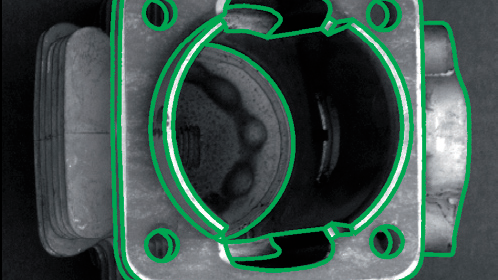

- Detect different types of defects on goods

- Identify cosmetic flaws of goods

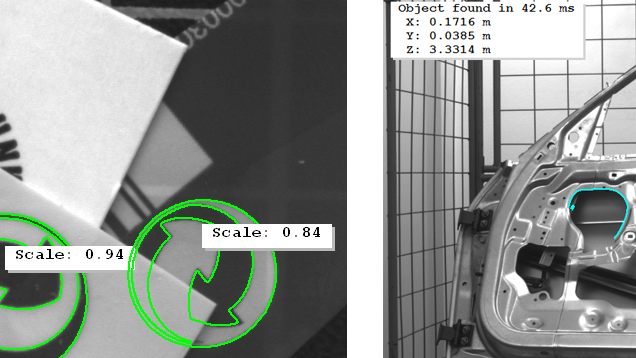

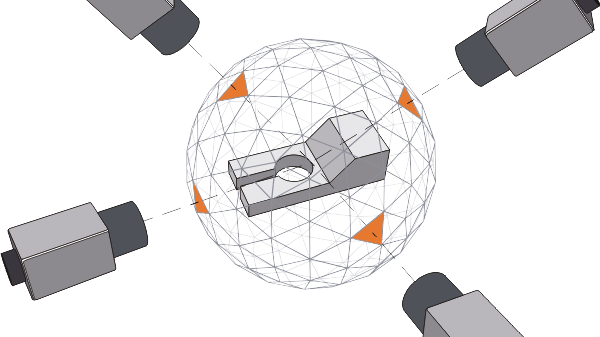

- Compare a good’s shape to, e.g., a reference CAD model

Very specific application examples are:

- Inspect laser-welded joints in lithium-ion battery production

- Identify hotspots during solar cell production to ensure full functionality

- Check whether ice cream (e.g., popsicles) fulfill requirements regarding shape and size

- Inspect car seat covers for surface defects

- Check electrode sheets for defects in battery production

- Checking beverage bottles for correct filling and defects on, e.g., the bottle mouth

Read more about the technologies you will find in our software products to help you with your quality inspection applications:

Quality inspection methods

Read more about how machine vision could be helpful in your industry or take a look at our customers success stories to find specific examples of the applications.