3D registration & perspective matching

3D registration

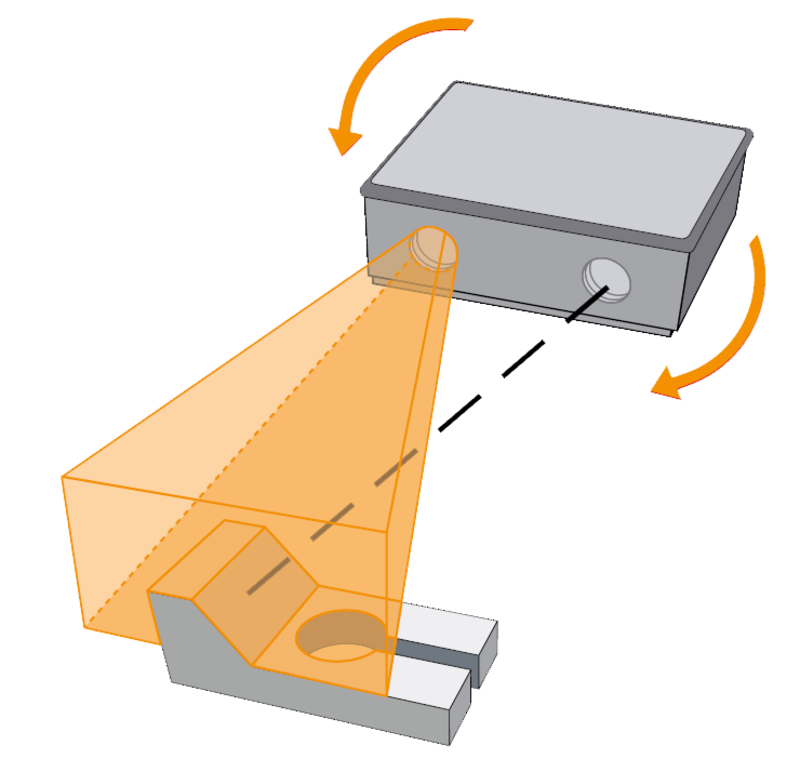

3D sensors directly capture the 3D coordinates of the visible points on the object surface. Using multiple 3D images of the object acquired from different points of view, the pairwise overlap of the 3D data is computed and a globally optimized shape is derived.

This technology is particularly suitable for 3D reconstruction, i.e. determining the 3D shape of arbitrary objects. The 3D object shape can be used in 3D matching, for quality inspection of 3D objects, or for the position recognition of 3D objects.

Our software packages support the direct derivation of the 3D object shape from 3D sensor data using 3D registration. Furthermore, our software offers advanced 3D shape processing techniques like smoothing, subsampling, and triangulation to prepare the shape model for 3D matching and object comparison.

Surface fusion for multiple 3D point clouds

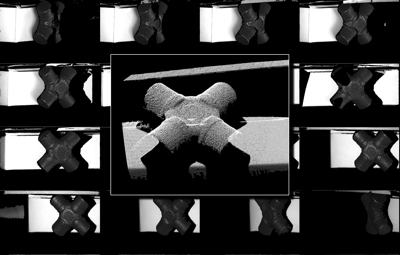

HALCON offers a method that fuses multiple 3D point clouds into one watertight surface.

This method is able to combine data from various 3D sensors, even from different types like a stereo camera, a time of flight camera, and fringe projection. This technology is especially useful for reverse engineering.

Perspective matching

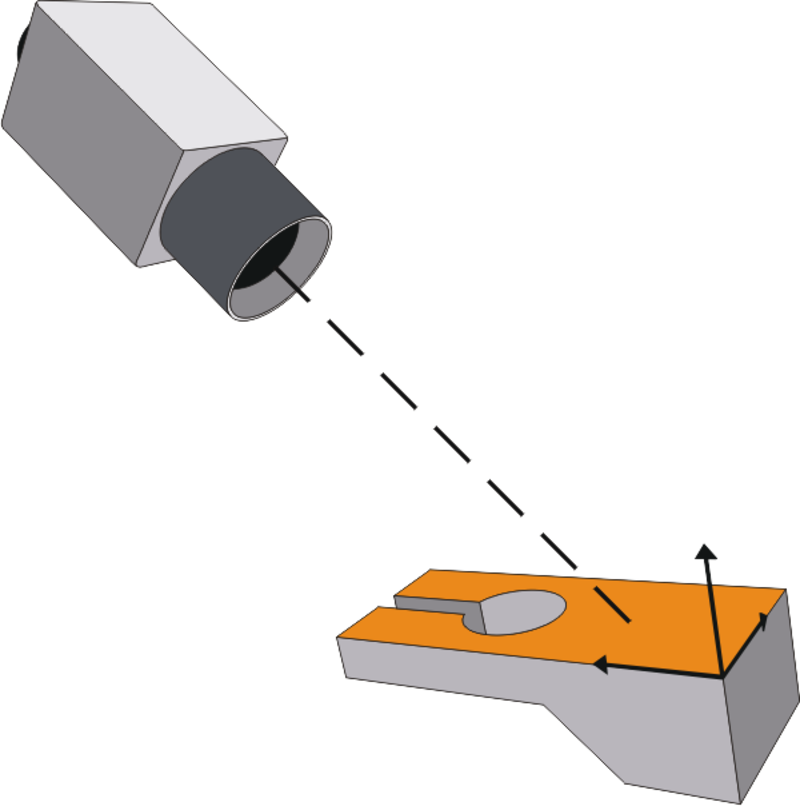

Instead of using the full 3D shape of an object, for many applications it is possible to restrict the model area to a planar part of the object. For arbitrarily shaped object parts, perspective matching allows to determine the 3D pose with only one camera. The model generation is done by training a sample image of the object typically inside a specified ROI.

Applications for this technology can be found within 3D alignment, e.g., applications for which the 3D pose (position and orientation) of an object must be found. Examples for such would be automotive and robotics applications, pick-and-place applications, and bin picking. A further possibility is the measurement of geometric features on complex 3D objects after 3D alignment.

Our software's perspective matching helps finding objects easily with only one camera. For perspective matching, our software packages provide two different methods suitable for two different classes of objects. Depending on the object's shape and appearance, our software offers both deformable matching, which is based on the shape-based matching technology (object edges), and descriptor-based matching, which uses so-called interest points.