3D Calibration for Inspection

Robotics | 3D Calibration | 3D Vision | Measuring

Stereo camera system eases highly precise measurement

If one wants to precisely effect 3D measurement of industrial components, the non-contact measurement via stereo images is a good option. Specially for these purposes, former SOLVing3D GmbH developed its camera system PrOMPT.stereo. This robust and compact hardware equipment can be used as a mobile measurement device, or alternatively it can be integrated in existing plants, e.g., for 100% inspection.

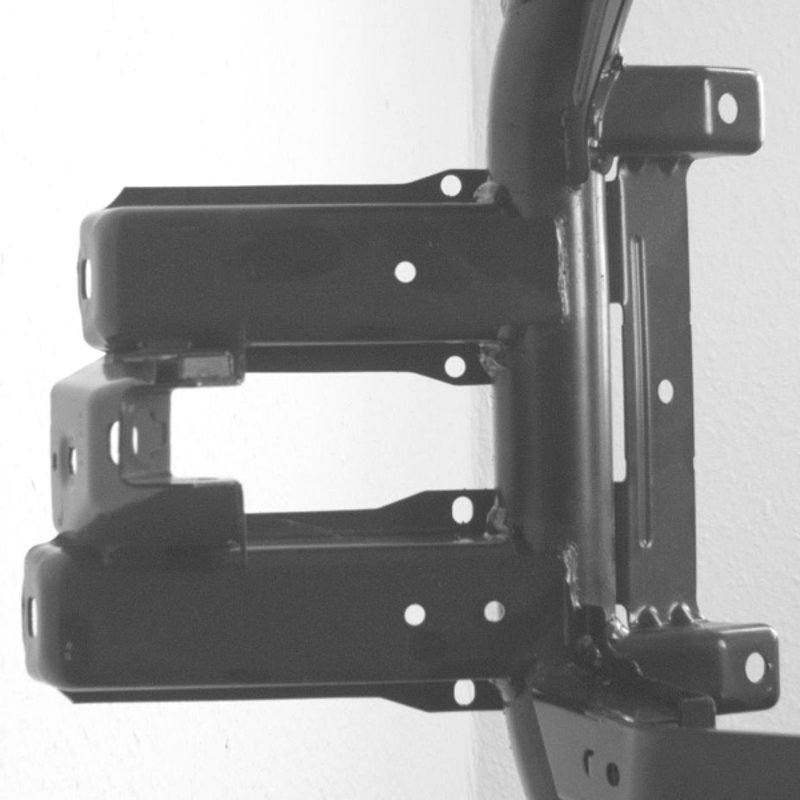

The device is composed of a robust aluminium frame (fig. 1) with changeable camera racks for a wide range of different cameras used in industry (Allied Vision Guppy, Marlin, Oscar; Baumer TXD; IDS uEye; Prosilica GC; Sony XCD V50, XLC X700, XLC 5000, XC HR57/58). All cameras can be accessed by the integrated machine vision software based on MVTec's HALCON.

The smooth exchanging of the camera racks is part of the system. Optionally, the system provides racks for laser devices to project lines and crosses in different executions. The exchanging of lenses enables the variation of the volume of interest from 70x50x20 up to 390x290x200 mm³. The precision of measurement ranges from 2 µm up to 20 µm.

This high accuracy (1 : 10,000) can be achieved by the highly precise system calibration. Caused by newly developed 3D calibration bodies and a special mathematic model, the calibration is not only highly accurate but also easy to handle. An assistant leads through the calibration process, therefore also unskilled users can handle it.

The entire image processing is based on the operators and algorithms of MVTec's machine vision software library HALCON. One special feature of the processing software is its robust point operator that not only detects marks but even precisely appoints boreholes under reflected light. The automation & assembly technologies GmbH, Bremen (Germany), employs the system for such borehole measurements in complex welded automotive assemblies. By inclusion of the stereo geometry for interpretation and intelligent image processing routines, boreholes can be measured by definition of only one point. During the teaching modus, this point has only to be approximately marked, the exact measurement of the 3D position and the diameter are automatically effected. Moreover, during the fully-automated inline mode, the measurements are completely controlled by the program. The target/actual comparison is executed under position- and rotation-invariancy by steric transformation. Thus, a precise positioning or guidance of the objects is not necessary.

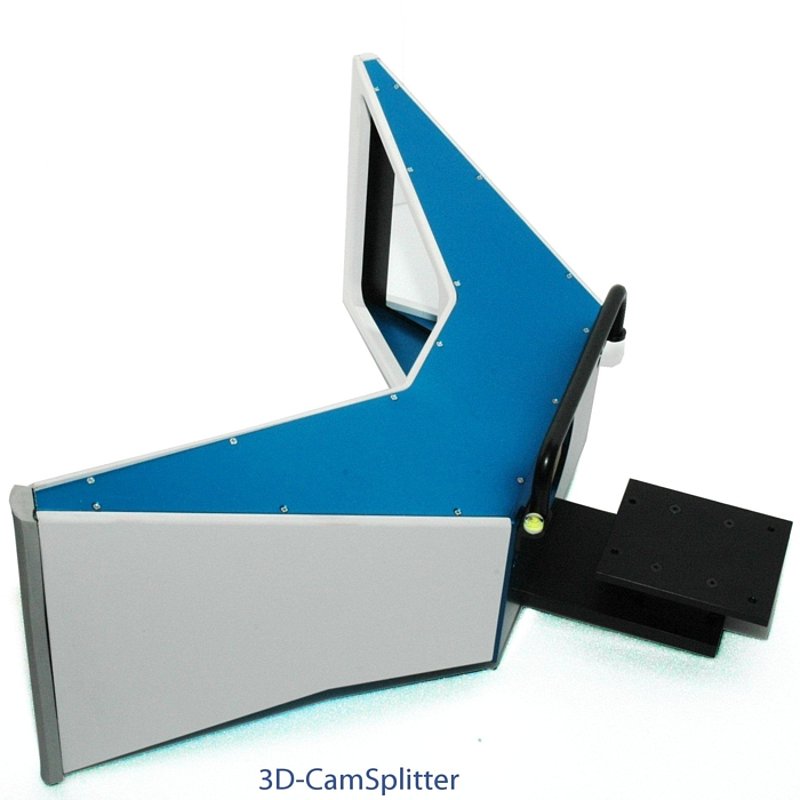

The cameras are delivered with precision lenses from Schneider-Kreuznach and different sensors with up to 6 mega pixels. Optionally, white, red, or infrared ring-lights as well as structured laser-lights are available. Furthermore, a high-end version of the PrOMPT.stereo camera system for up to 100 Hz recording frequency can be received. Among the referred example of the borehole measurement, the Continental Automotive Systems (Hanover, Germany) employs the PrOMT.stereo camera system for deformation measurement of pneumatic shock absorption devices. Furthermore, within the scope of crash tests the system software is used by the Volkswagen AG (Wolfsburg, Germany) to calibrate high speed cameras upgraded to a stereo camera by a mirror device.

Author: Dr. Lutz Kreutzer

All product names, trademarks and images of the products/trademarks are copyright by their holders. All rights reserved.