3D Vision Guided Robotic Assembly - Kinemetrix

Machinery | Robotics | 3D Vision | Matching

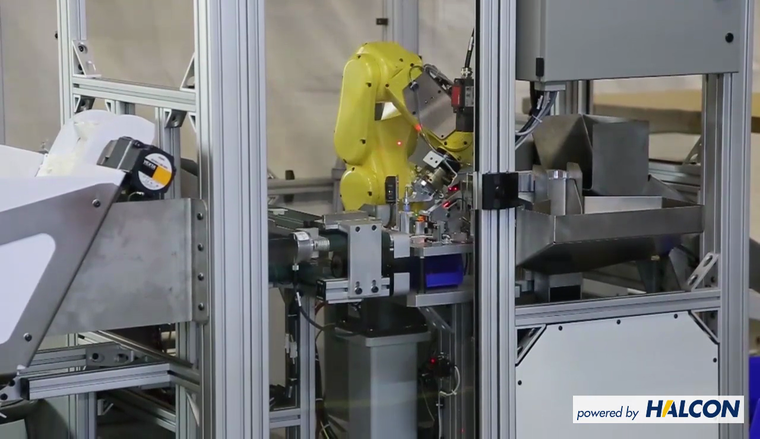

Using HALCON's surface-based 3D matching technology and 3D point cloud data, the position and orientation of parts on an automated clip assembly cell are determinded.

Kinemetrix, based in Lexington, KY, specializes in advanced solutions for robotic automation. Using the HALCON machine vision software, they recently built a automated clip assembly cell in which parts are fed onto a conveyor in arbitrary 3D orientation, then picked and rotated by an articulated robot so that a plastic clip can be inserted. The system uses a Ranger 3D laser triangulation sensor from SICK to create a 3D point-cloud of the parts as they pass by on the conveyor. The parts' position and orientation is determined from this point cloud data using HALCON's surface-based 3D matching technology. The parts are found within a close tolerance that allows the robot to correctly align them with the clip assembly mechanism. Based on the 3D pose returned by HALCON, the system determines which parts are in a suitable orientation to be picked for assembly. The remaining parts are recirculated. Jim Peyton, President of Kinemetrix, attested to the time and cost saving benefits of using HALCON stating: "We've learned that successful random-fed robotic picking requires careful design of system, gripping, vision, and path planning. HALCON provides extremely fast, robust, and powerful tools for 3D vision that allow us to focus more on the mechanical and system-level design elements. A noteworthy example from this project is the absence of a re-grip station. With attention to system calibration, we achieved 1mm volumetric accuracy directly from a random pick. That allowed us to meet the required cycle time using only one robot and eliminated part-specific tooling. As a result, we were able to provide our customer with a future-proof, agile system at a cost that's competitive with fixed automation."

For more information on this application and other innovative solutions by Kinemetrix, visit: www.kinemetrix.com.

Author: John Campbell Video material kindly provided by Kinemetrix.