HALCON supporting the cutting of textile materials

Glass, Metal, Paper, Foil & Printing | Machinery | Matching | MorphologyT3LAB deals with technology transfer in the field of information and communication technology (ICT) and specializes in the realization of ICT solution in Industry 4.0. VisionLab is an open-innovation branch within T3LAB that develops applications based on industrial cameras and computer vision libraries.

The project

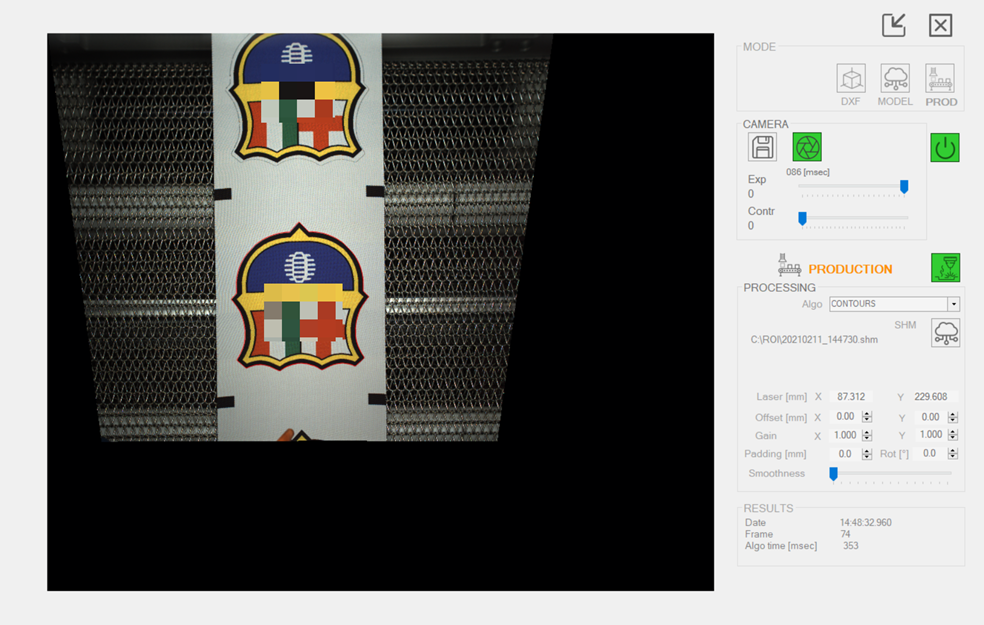

In this project, MVTec HALCON was implemented to minimize production rejects and improve quality control in the production of textile materials.

As a first step, the specific contour of the working element is extracted from the image. Next, the cutting coordinates get adapted to the related characteristics in order to compensate the production tolerances as well as the mechanical deformations caused by the working machine.

Two different approaches are available for the extraction of cutting coordinates from images, both using morphology and matching operators. One way is to automatically extract the outermost contour (CONTOURS), the other is to adapt the cutting coordinates of a reference model using the shape-matching technique (MODEL-SHAPE).

I. Contours:

This approach uses the automatic extraction of the contour for each label and requires neither a model nor a starting contour. The contour must be distinguishable from the background. This approach uses the function background set in combination with edge detectors and threshold. The processing times are significantly lower than the shape-matching, making it suitable for cutting labels with non-precise processing. However, it is less robust to the exposure and background conditions of the textile.

II. Shape-matching technique:

This approach is based on the model creation and a starting contour. The model is the reference, where the warping of the cutting curves is defined (rotation, translation, and scale). The latter can be either created by an operator within the HMI application or imported using a DXF file. This approach uses HALCON functions for model creation and model application. It is more robust to the background and has higher performance but can only be used for identical labels.

The setup

The vision system is composed by a Teledyne DALSA C2420 color camera with 5Mpx of resolution and F=12mm optics. The camera is positioned alongside the cutting laser, which is positioned orthogonally to the cutting plane. The acquisition system is synchronous with the cutting system and allows to reach a maximum speed of 5 labels per second. The speed changes according to the cutting area and the characteristics of the element itself.

Why HALCON

“MVTec HALCON allows, both in the acquisition phase and in the development phase, to create applications in a fast and robust way.” – Federica Fergnani, T3LAB