Individual Packet Identification System for Handwritten Characters – Eckelmann

Packaging & Logistics | OCR & OCV

Eckelmann AG from Wiesbaden, Germany, has modernized the stock receipt of a big warehouse based on powerful standard components.

A descriptive example for modernizing an automated packet identification system is the warehouse storage of the mail-order house WITT Weiden, Germany. The OCR has to identify standard labels with handwritten characters by about 400 suppliers around the world. The identification rate must be higher than 96%. ECKELMANN AG, Mainz, developed this application based on HALCON that perfectly fits to the existing environment and the existing proprietary inventory control system.

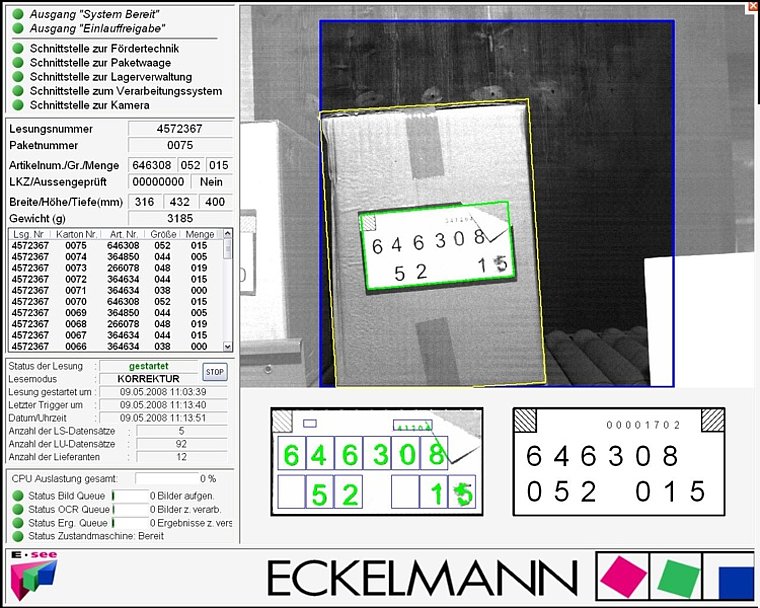

The goods are delivered via motor trucks, packed in packages of only three standard dimensions. These boxes are guided trough several registration conveyor belts operating automatic weighting, measurement, and identification of the single boxes. The ascertained data are subsequently transferred to the proprietary warehouse management systems. Identification and measurement of the boxes is performed by an imaging system which was substituted within a modernization process. The challenge was to identify the boxes through arabic numerals (item number, quantity, and size) written on standardized labels (Figure 1). That means that the system must be able to identify and classify printed, stamped, and handwritten digits. This functionality is widely known as Optical Character Recognition (OCR). Each line must handle 5,000 packages a day with a capacity of about 40 packages each minute. All components were selected in such a way that in the case of a process upset it is sufficient to only change the PC. If necessary, the recovering of the system can be done without problems within only one hour because the hard drive mirroring is done via network.

The imaging software is based on the standard software library HALCON 8.0 from MVTec. The application building is supported by HALCON's integrated development environment (HDevelop). Affected by a long transport, the labels often are polluted or damaged. Thus, the label localization and the segmentation of the characters can be extremely complex.

The classification of the handwritten characters is partly multi-stage processed by using different methods, for example the support vector machine provided by HALCON. "The implementation of the image processing as we planned it was only possible by several exclusively special HALCON 8.0 attributes", says Arno Dewald, ECKELMANN's responsible project engineer.

After a first run of classification for a character sequence under the appliance of neural networks, a plausibility check occurs in adjustment with the total quantity of allowable results. If necessary, a second classification process runs with an alternative method (particularly the support vector machine has proved to be very powerful).

Furthermore, the machine vision software detects the size of packages. Because only three different packages are permitted, the image software must only detect one side of a package to conclude the size. Based on this data, the system decides if two small packages or one bigger package are stacked on one storage tray and location. The result of the new application exceeds all expectations of WITT. A first evaluation over the time-frame of one month showed that the identification rate was 100%. The processes of the OCR as well as the entire status of the plant are visualized through clearly arranged user interfaces (Figure 2). By data exchange with the warehouse management system, different plausibility checks are processed. Against this plausibility check, the automatic labeling of the package happens by a newly printed plain written label (Figure 3).

"We are very content regarding the project settlement and the performance of the application", says Sabine Schaumberger, project manager at WITT Weiden. "Even during the fast-paced Christmas business, the launch of the application without interrupting operations was no problem."

Authors: Winn Hardin, Contributing Editor, and Dr. Lutz Kreutzer, MVTec Software GmbH

Article kindly provided by Vision Systems Design. Eckelmann AG is an MVTec Certified Integration Partner. All product names, trademarks and images of the products/trademarks are copyright by their holders. All rights reserved.