Inspection of drilled holes on furniture parts with the help of HALCON

Machinery | InspectionIn collaboration with our distributor The Imaging Source, industrial automation solutions provider Teomsi Electric Company developed an inspection system in cooperation with Ecolor for their furniture factory.

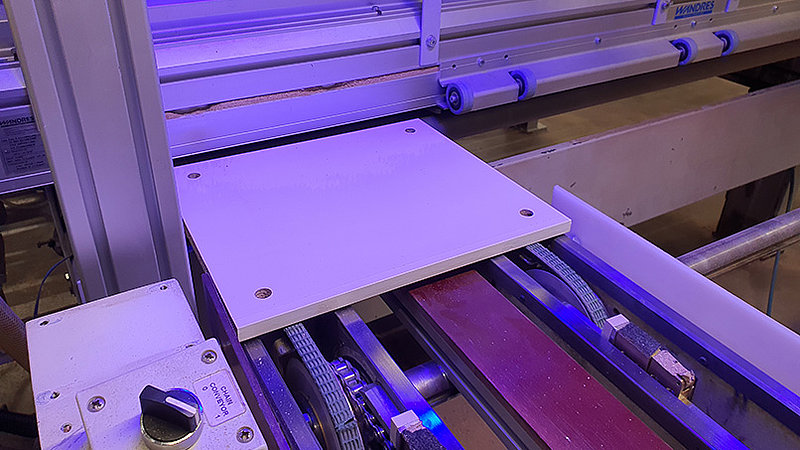

Teomsi integrated vision systems into the drilling machine for wood panels to detect the presence of drill holes. For various reasons (broken or missing drill bits, stops due to an error in the machine cycle), it may happen that one or more drill holes are missing. If this happens, the furniture part cannot be assembled into the final product. With this system, Ecolor was able to significantly reduce the error rate and increase the satisfaction of their customer, a leading global furniture retailer.

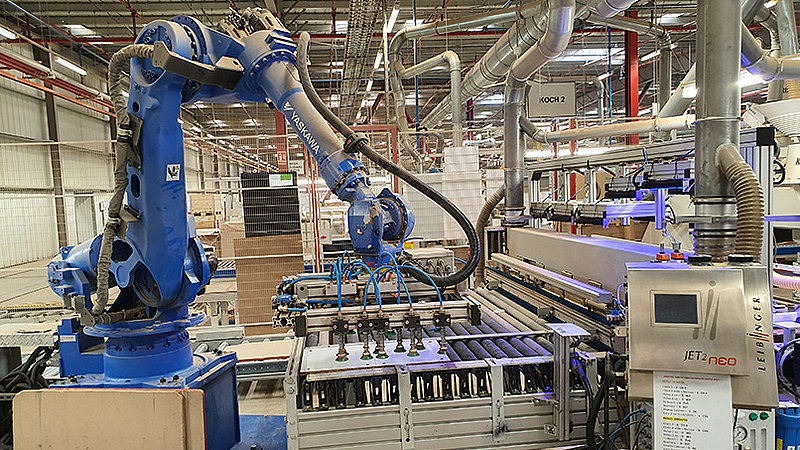

The production line consists of an automatic drilling machine and two robots, one for feeding the machine with parts and one for staking the parts after drilling. The drilling machine drills holes according to a product recipe, which contains the number of holes, diameters, positions etc.

The vision system

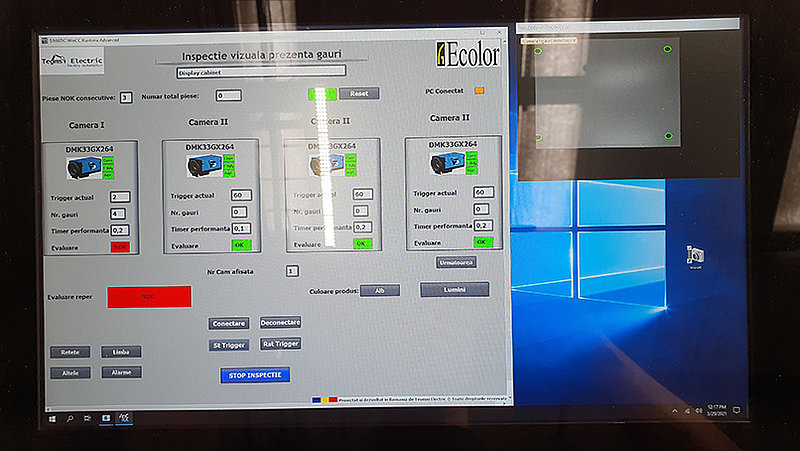

On the hardware side, the vision system consists of a panel PC, a PLC, one or more TheImagingSource cameras, encoders, sensors, etc. The PLC provides the connection to various industrial machineries (PROFINET, PROFIBUS, MPI, Digital I/Os etc.).

Teomsi chose HALCON machine vision software because of its flexible architecture and diverse capabilities. In addition, the great support from The Imaging Source was another reason for them to work with HALCON. The PC runs HALCON and the visual interface for the operator. HALCON communicates with the PLC via a socket connection exchanging data using a number of bytes.

According to the inspection recipe, in which the necessary data for the inspection are stored, a decision is made after the part inspection: OK or NOT OK.

The process is as followed:

- The PLC sends the trigger signal according to the presence sensor and the encoder.

- Camera is triggered.

- Image is acquired.

- Holes are detected and counted by HALCON.

- Number of holes is sent to the PLC and compared with the recipe.

- Depending on the comparison OK or NOK, a signal is sent to the drilling line, to the stacking robot and to HALCON.

- When the drilling line receives a NOK signal, it stops the cycle, illuminates an error light, and displays an alarm on the HMI indicating the NOK part.

- The error message received by the stacking robot guide it to place the part on another stack.

- If the error message is received by HALCON, the current image is saved on the hard drive with a date stamp.

Text and images are kindly provided by The Imaging Source.