Machine Vision Solves "Needle-in-a-haystack" Problem for Small Parts Manufacturer, Developed by Data Systems

Machinery | Packaging & Logistics | Matching | OCR & OCV

Data Systems, Inc. is an experienced developer of vision systems for laboratory and manufacturing environments.

Problem

A small parts manufacturer needed to insure that each customer's order contained only the correct size, style and type, coating, and marking of each part. Because of the wide variety (over 300,000 sizes and designs and volumes ranging from 10 to 5000 pieces) of parts, it was possible that the final batch could contain the wrong part. Additionally, each part needed to be laser marked with the appropriate nomenclature. Since their customers used these parts to make other parts, it was critical that the shipment contained exactly what was ordered, otherwise a wrong part, inadvertently used, would produce many parts that had to be scraped.

Solution

A pattern recognition technique using the first external reference category Rule- or Logic-Based was selected and implemented in an automated conveyor system to reject all parts that did not match the trained classifications patterns. Additionally, the second external reference category Pattern Matching technique was implemented for a specific style and type of part. Test patterns were automatically pre-selected based on the part size and type chosen by the operator during the train cycle. Once the system is trained the sorting is done on a continuous conveyor and parts handling system. The accepted parts are delivered to final shipment bin and the rejected parts go into a reject bin for further analysis and inspection.

Camera Implementations

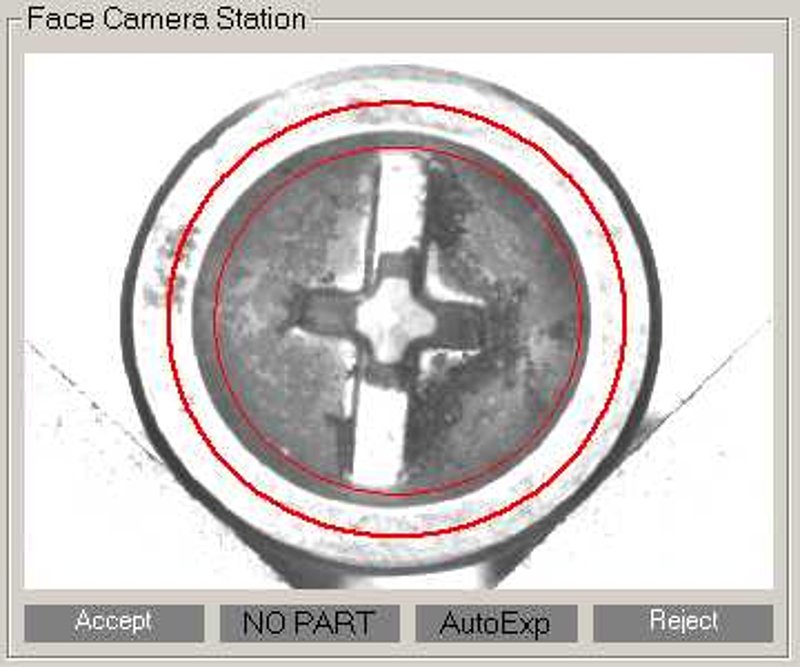

To insure sufficient testing of each part, three cameras and a PCI controller board are used to acquire several views of the part for further processing within the vision system software. Since it is important to view all the camera images in real-time, an asynchronous loop is used to acquire, process images, and communicate with the PLC controlling the parts handling system.

HALCON - The Software "Heart" of the System

The HALCON machine vision software is used to manipulate and process all images. HALCON operators support the train mode and subsequently the run mode of the system. HALCON's edge detection is used to find the diameter and length of parts based on the images acquired by the spin station camera. Here, HALCON's intensity inspection operator is used to determine the part's surface finish. The retrieved information is also used to determine the part's orientation.

HALCON's edge detection and pattern matching are used for processing the images of the face station camera. Additionally, the intensity inspection is used in conjunction with the Opteon camera exposure control to automatically adjust the camera for part surface reflection variations.

A third Opteon camera, with a Navitar motorized auto zoom/focus lens, is implemented to acquire the top view of the tip portion of the part. Since the part size may vary, it is necessary to automatically adjust both focus and zoom. Here, HALCON's edge detection guarantees a robust determination of pallet location and tip length of the part.

Author: Larry Zagorsky, Data Systems, Inc.

All product names, trademarks and images of the products/trademarks are copyright by their holders. All rights reserved.