Semiconductors

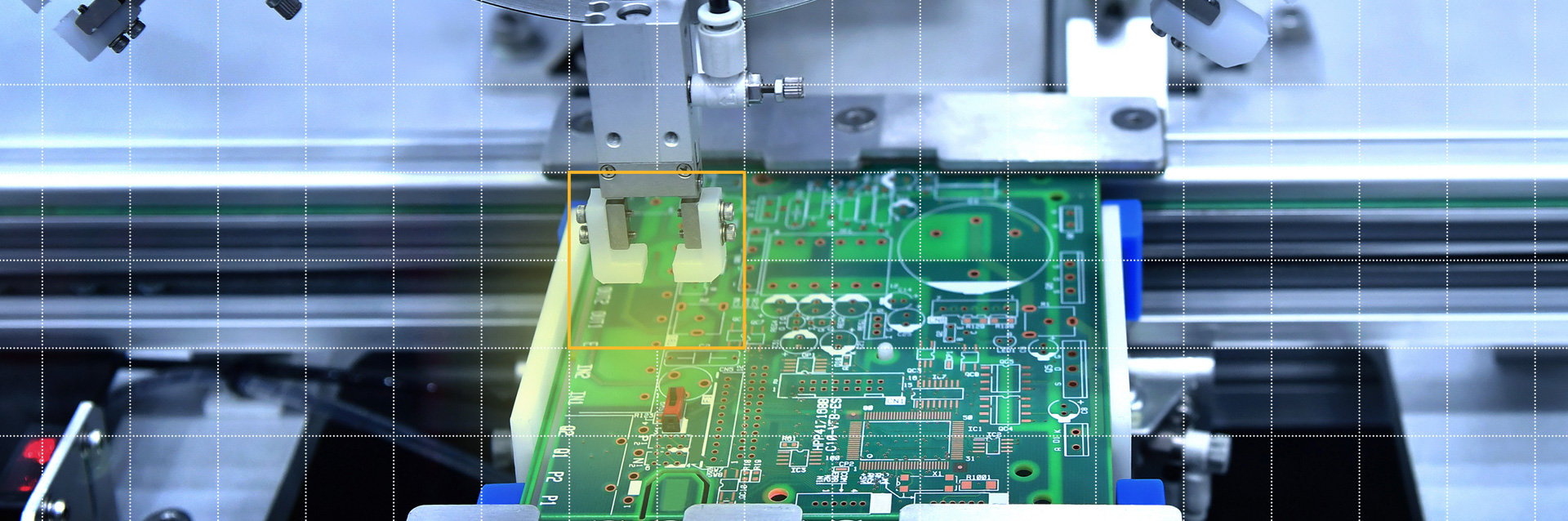

The Semiconductor industry continues to be one of the largest users of machine vision and a driving force in the evolution of machine vision technology. Continuous improvement of production yield through stringent manufacturing process control demands state of the art machine vision inspection, measurement, matching, and classification capabilities among others.

MVTec’s software provides best-in-class tools for precision alignment of wafers, detailed wafer, die, and ball/wire bond inspection, defect classification, matching, accurate measurement of features in 2D and 3D, 3D robot guidance, reliable identification, and much more.

As the leading innovator in machine vision software technology, MVTec helps semiconductors manufacturers achieve new milestones in cost reduction, yield improvement, and the advancement of new manufacturing technologies as well as production scenarios that require the collaboration of humans and robots.

Methods and techniques

- Surface inspection

- Defect recognition

- Completeness inspection

- Positioning & alignment

- Bar code/sata code reading

- Object identification without code (SBI)

- OCR (character recognition)

- 2D/3D matching

- 2D/3D measuring

- 3D vision

Application examples

Find out how customers use MVTec software to develop high-innovative solutions for semiconductors.

Free evaluation of your machine vision application

Do you want to know if we have the right solution for your special industry? Send us your software application design and our experts will review it!