3D Calibration

With 3D calibration, you establish the relationship between a camera and a corresponding object. For robotics applications, the relationship between the robot and the camera is determined as well. With this technology, you get an explicit and accurate description of your area or line scan camera: A set of so-called internal and external camera parameters map the image coordinates to real world coordinates.

MVTec’s software includes operators and development assistants for the calibration of internal and external camera parameters. For the calibration, images acquired from hypercentric, pinhole and telecentric area scan cameras as well as line scan cameras can be used.

Calibration capabilities include:

- Self-calibration of rotating cameras and of lens distortions

- Correction of lens distortions for images, contours, and points

- Transformation of contours and points (camera coordinates) into real world coordinates

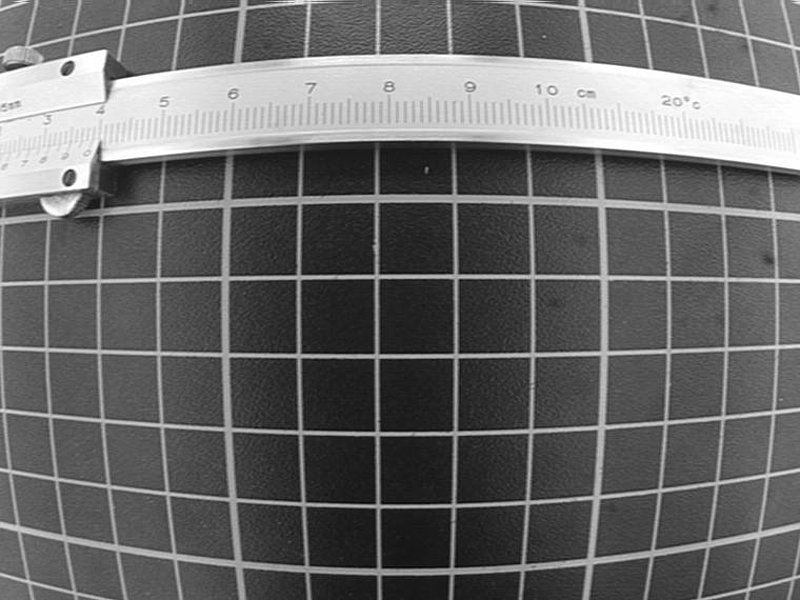

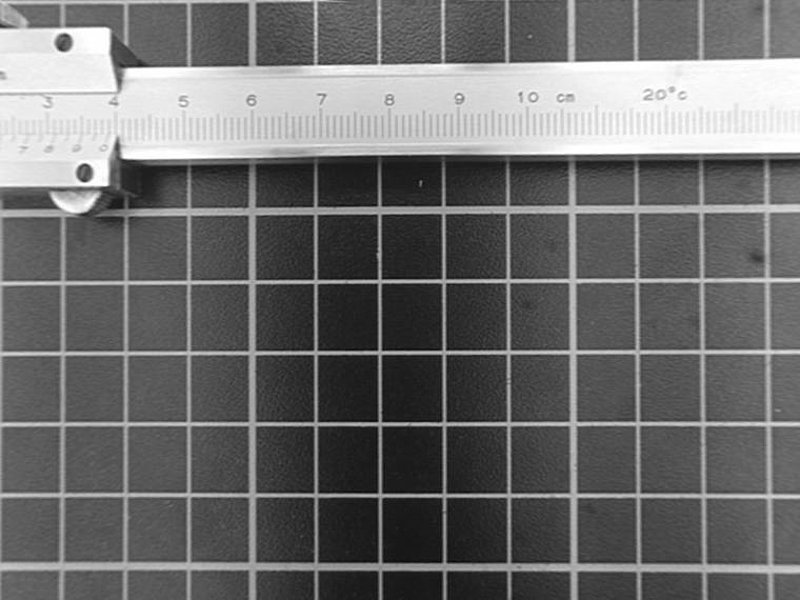

- Rectification of images (removal of lens and perspective distortions)

- Hand-eye calibration for transforming camera coordinates into robot coordinates

Highest accuracy

Calibration is critical for achieving the highest possible accuracy in your machine vision application. MVTec software enables you to calibrate your camera very easily. With a powerful set of operators and a precision-manufactured calibration plate, you can remove lens distortions from your images and measure objects in world coordinates.

Multi-view 3D calibration

By taking multiple images of a calibration plate placed arbitrarily throughout the camera field of view, an explicit and precise 3D coordinate mapping of the field of view can be calculated and complex distortions can be corrected. The internal and external camera parameters obtained from the calibration procedure map the image coordinates from the camera to real world coordinates that the user can understand. MVTec’s calibration procedure allows for subpixel-accurate measurements down to 1 µm in a field of view of 10 mm – also with line scan cameras. HALCON's hand-eye-calibration is crucial for robotic applications. Amongst others, HALCON provides calibration also for Scheimpflug optics and hand-eye calibration for SCARA robots.

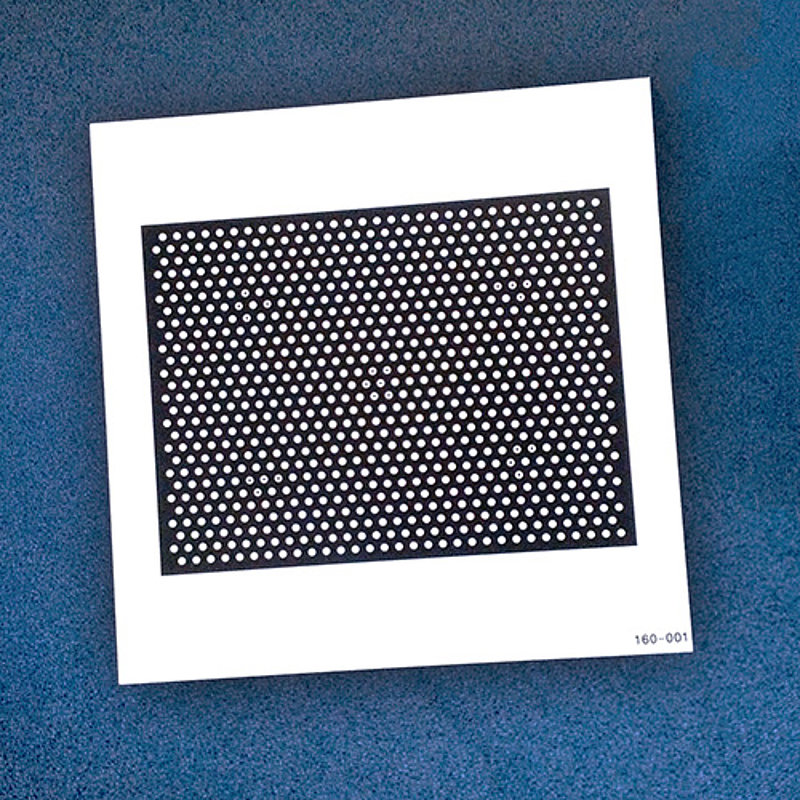

Calibration plates

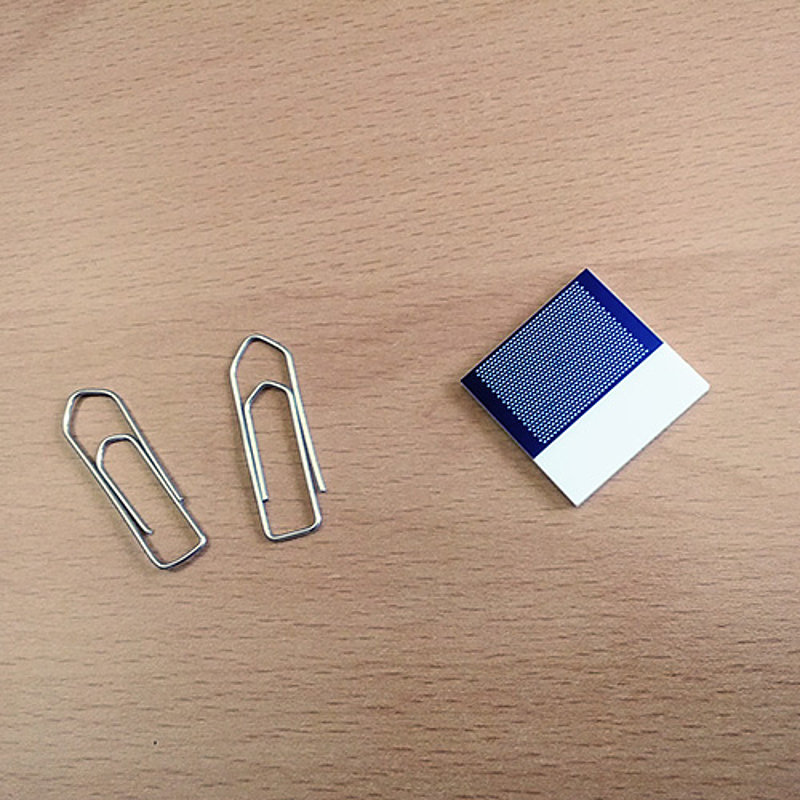

MVTec provides precision-manufactured calibration plates to its customers. The plates are necessary to accurately calibrate a machine vision setup. MVTec’s calibration plates are available in different materials and in sizes ranging from 2cm×2cm up to 320mm×240mm. Contact your local distributor for assistance with choosing the right plate size and material for your application.

Please note that calibration plates are only available to MVTec Software customers.