Machine vision for food and beverage industry

The production, processing, and packaging of foods are highly competitive and fast-paced industries. To maintain consistent quality, competitive prices, and to quickly respond to ever-changing food trends, manufacturers turn to machine vision technology to control manufacturing processes and improve production efficiency.

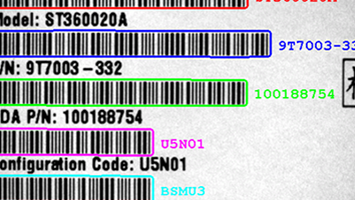

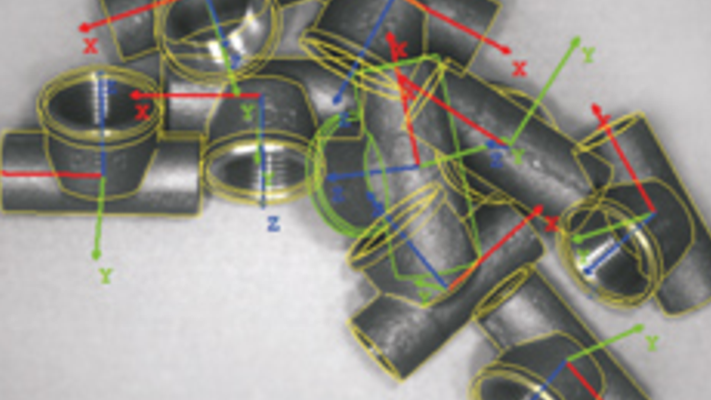

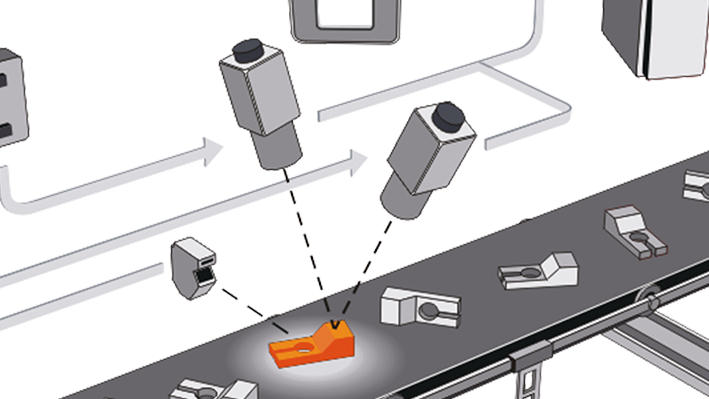

Whether automating agriculture with vision-guided farming equipment, maintaining consistent standards of quality through high-speed sorting, optimizing yields of robotic cutting and portioning systems, detecting contaminates in packaged foods or moldy fruits (by using hyperspectral or multispectral cameras), accurately identifying products for packaging and labeling, or a need for reliable track and trace standards, MVTec provides technology for producers and packagers alike to achieve efficient and consistent production, and keep up with consumers’ ever-changing demands.

Machine vision optimises process chains in the food and beverage industry

As in most industrial sectors, value chains in food and beverage production are becoming increasingly automated and digitalised - keyword Industry 4.0. Accompanying technologies that significantly support and optimise this process play an important role - first and foremost machine vision. This enables objects along the entire value chain - from production to quality assurance to logistics - to be detected accurately and automatically. Companies in the food industry benefit from integrated processes, higher productivity and cost savings. Find out which success stories are hidden behind the value chain.

Well-founded evaluation of a wide range of quality features

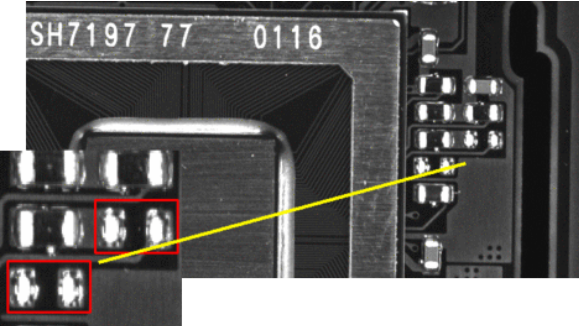

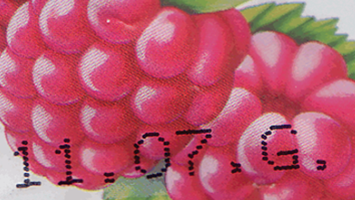

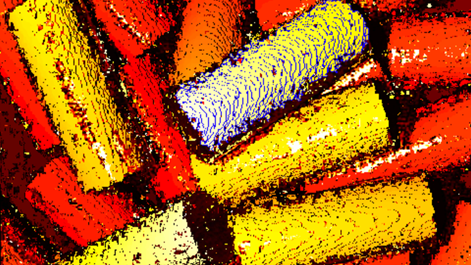

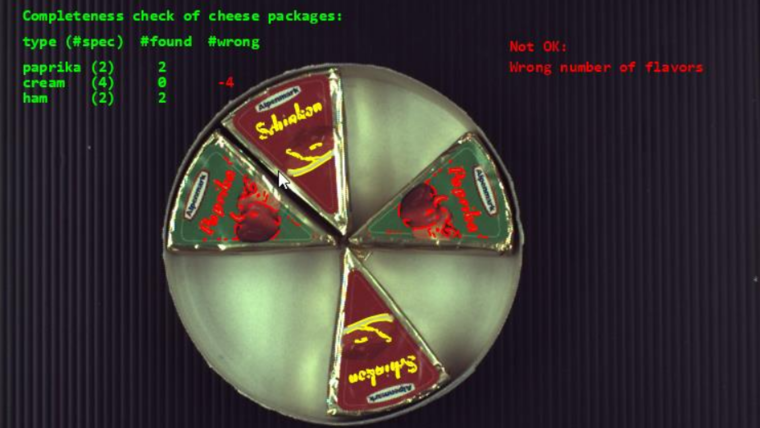

Industrial image processing is not only suitable for identifying and reliably processing food objects. It can also be used to detect and localise product defects with the highest precision. Deviations from the target state can occur in many different forms, especially in the food and beverage industry.

MVTec's machine vision software is capable of soundly evaluating a multitude of different quality characteristics and detecting defects. This results in very reliable defect detection rates and makes machine vision so valuable for automated inspection processes in the context of quality assurance.

Application examples

- Baking industry: The degree of browning of hamburger buns can be precisely determined by means of a 2D colour analysis. Based on the colour values on the surface, the software reliably detects if the buns have been baked too crispy. These can then be automatically sorted out before they are packaged and brought to the retailer. The technology impresses with its high speed: objects or defects are identified within milliseconds. This means that the detection and inspection processes can be automated and accelerated, even for large quantities.

- Biscuit production: the technology can be used to automatically check the chocolate coating on biscuits. Here, the image processing algorithms recognise from the brightness structure of the surface whether the icing has been applied correctly. Thanks to anomaly detection, only images that show perfectly glazed biscuits are required for training. Otherwise, the effort here would be disproportionately high because, after all, countless different variants of faulty or incomplete chocolate icing are conceivable.

There are many more examples like in the rice production, in ice cream packing or the quality control of wheat. To name just a few. Do not miss our success stories to find out how your production can benefit from machine vision solutions.

Machine vision methods in food and beverage industry

Free evaluation of your machine vision application

Do you want to know if we have the right solution for your special industry? Send us your software application design and our experts will review it!