Anomaly detection

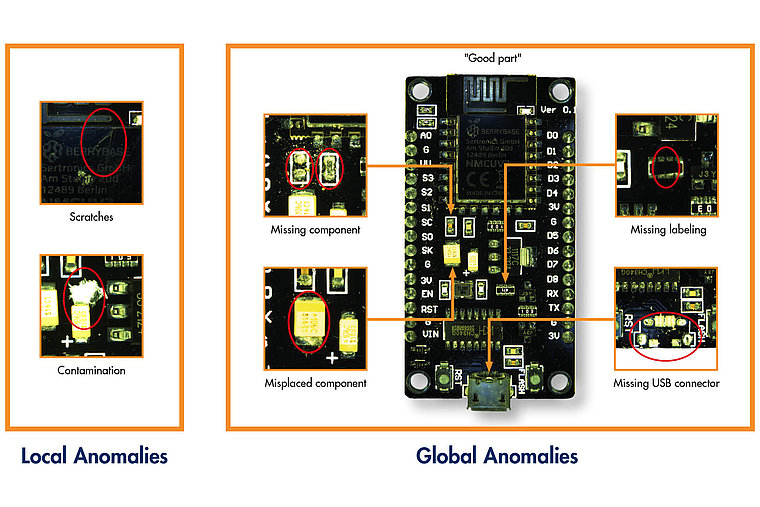

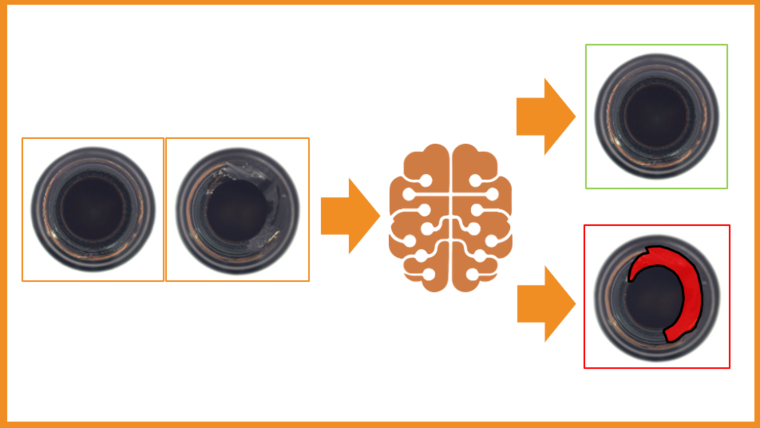

Deep-learning-based anomaly detection facilitates automated surface inspection for, e.g., detection and segmentation of defects. The technology is able to unerringly and independently localize deviations, i.e., defects of any type, on subsequent images. Model training only requires images of samples without defects. As opposed to other deep learning methods, no labeling effort is required. During inference, anomaly detection segments the areas of images that deviate significantly from the training images.

Global Context Anomaly Detection

BENEFITS:

- Detect anomalies in global context

- Powerful algorithms

- No labeling required

- Only good images needed

The new "Global Context Anomaly Detection" is a one-of-a-kind technology, which takes into account the logical content of the entire image. This technology makes it possible to detect entirely new variants of anomalies like missing, deformed, or incorrectly arranged components. It presents completely new possibilities: For example, the inspection of printed circuit boards in the semiconductor production or the inspection of imprints.

Anomaly detection

BENEFITS:

- No labeling required

- Only good images needed

- Smaller number of images

- Fast training and prototyping

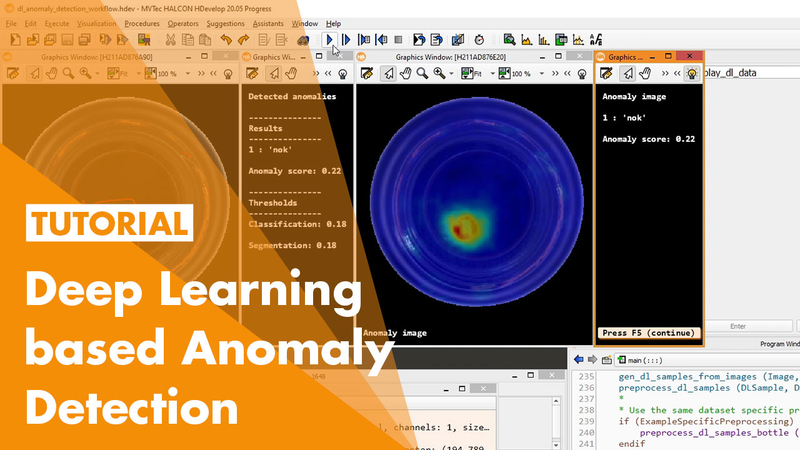

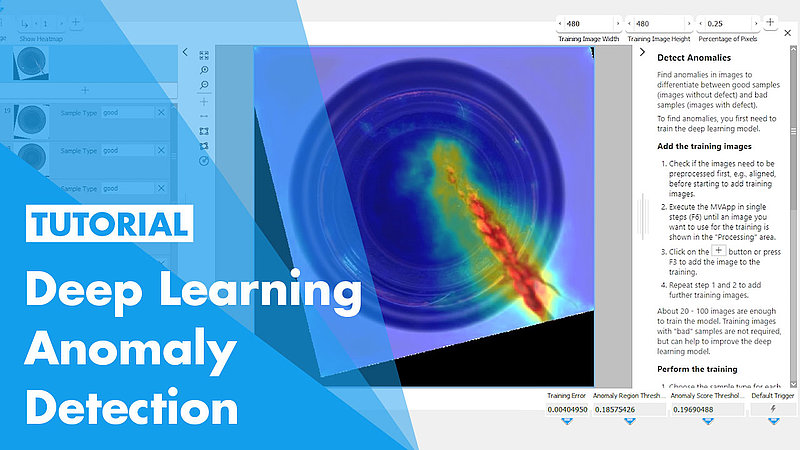

Anomaly detection without the global context functionality requires only a small number of images. Training a new network can mostly be done in a matter of seconds or minutes, allowing users to perform many iterations to fine-tune their application without sacrificing a lot of precious time. Furthermore, the inference times are very short.

Helpful tutorials to learn how to use anomaly detection

Learn more about the other methods:

Image Classification | Object Detection | Semantic Segmentation | Edge Extraction | Instance Segmentation | Deep OCR