Machine vision – suitable for use (almost) anywhere

No, industrial image processing (machine vision) has nothing to do with Photoshop. However, its importance and range of potential applications are at least just as exciting.

Automation and digitalization are finding their way into ever more business sectors. Realigned supply chains, a skills shortage, and ever shorter product lifecycles are just a few of the issues that are encouraging their diffusion. Machine vision is increasingly becoming a key technology. It paves the way for extensively automating and optimizing processes along the entire industrial value chain.

Over the past few decades, machine vision has increasingly become an indispensable technology for companies from the broadest range of sectors. As the “eye of production”, machine vision constantly monitors all manufacturing and logistics processes. But what does machine vision look like in practice? What components are required, what exact benefits does the technology offer, and where exactly can it make best use of these? This article aims to answer these and other questions.

Let’s start with the basics: A machine vision application requires hardware and software components. In terms of hardware, we need what are known as image acquisition devices. These can be cameras or sensors positioned at various points within the production environment. The devices record processes and generate large volumes of image data. In a pictorial comparison to the eye, the cameras and sensors represent the lens through which events are perceived.

Machine vision – the eye of production

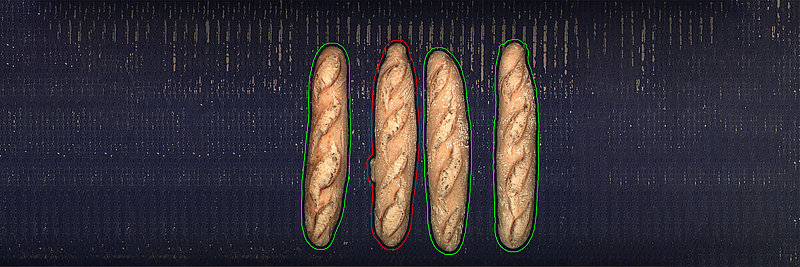

As with a human brain, the information captured has to be processed in order to be used. This is done by machine vision software integrated into the process, which processes the data and provides the results for further use. A number of methods and technologies are available to this end. In particular, deep learning, a form of artificial intelligence, opens up new and exciting fields of application. What makes machine vision special is that, like the human eye, it is able to identify the broadest range of objects and correlations and put them in the context of production. This opens up wide-ranging possibilities for uses in all sorts of different processes. For example, objects in the goods cycle can be automatically identified and classified. How? There are several possibilities. Firstly, this can be done on the basis greater reliability and precision than the human eye could ever do. But that’s not all. In the context of networked production, the products concerned can be automatically classed as rejects and removed before they get any further in the logistics process chain.

Machine vision and robots – a dream team

Machine vision can also be used for wide-ranging applications in the field of robotics. Classic and collaborative robots, i.e., robots that can work directly with humans without a protective device, use the technology to precisely grasp, process, and set down all kinds of objects. The robot’s added value increases as it can perform more tasks independently. This makes it possible to thoroughly automate production. One example of this is the use of robots in logistics, or to be more precise for loading and unloading pallets: Here, the robot arm is equipped with an industrial camera. Machine vision software of purely external features such as color, shape, or texture. Machine vision can also identify objects through the use of number or letter combinations printed on them.

Where can machine vision be used? The question is more so: where can’t it?

Whether in the automotive industry, the machinery and plant engineering sector, or food and drink production, machine vision can offer support everywhere. Also, the electronics industry particularly benefits from the technology, for example semiconductor manufacturing. The many production steps and high levels of precision make this a particularly complex process, so it goes without saying that quality control is of immense importance. And this is where machine vision can naturally be used for the demanding inspection tasks.

Time is money

Automated inspection using machine vision is far quicker, the results are objective and reproducible, and there are no risks of the inspection quality deteriorating e.g., due to tiredness or the monotony of the task. This makes machine vision particularly predestined for high-speed applications. As an example, it takes less than 10 milliseconds to determine the position of any object with the utmost precision. In comparison, it takes 300 to 400 milliseconds to blink.

But that’s not all that machine vision can do. A whole range of application areas open up with regard to networked production or in combination with the cloud. For example, large quantities of image data can be used for predictive maintenance. Any necessary machine maintenance, for example as a result of wear, is now identified immediately, ultimately preventing machine downtime and reducing maintenance costs.