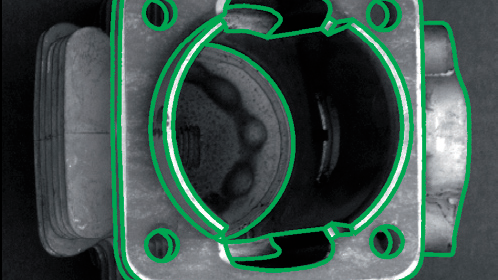

Position recognition

The highly accurate recognition of positions is essential for strongly automated production workflows, e.g., in which a multitude of different systems need to be precisely aligned to each other. One major use case are tasks in which objects need to be handle for further processing, e.g., in Pick & Place applications or for automated assembly processes. Another typical use case is the detection of reference marks. These are used in many of automated processes to make sure, e.g., work piece carriers can be aligned accurately for processing. With position recognition this marks can be detected with very high accuracy.

Machine vision systems are called on here in a number of areas:

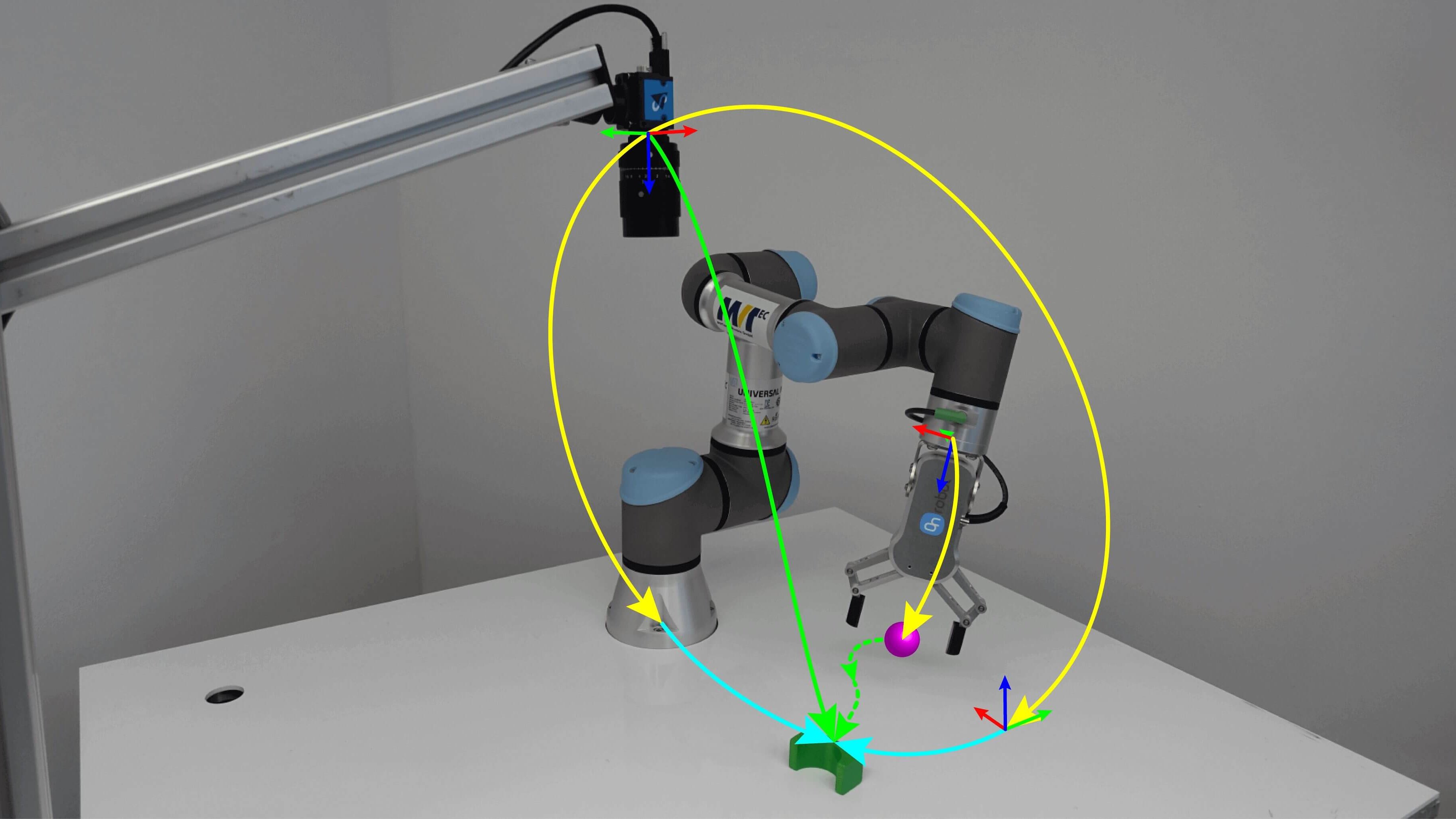

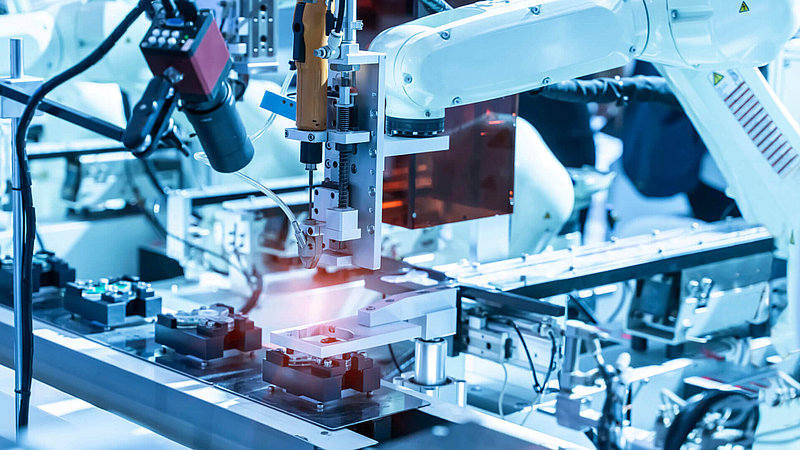

- Highly accurate picking and placing of objects for further processing

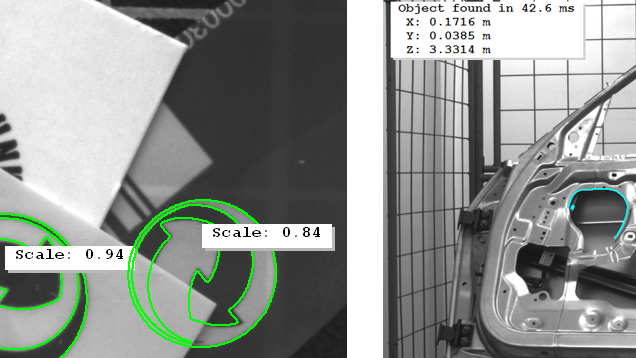

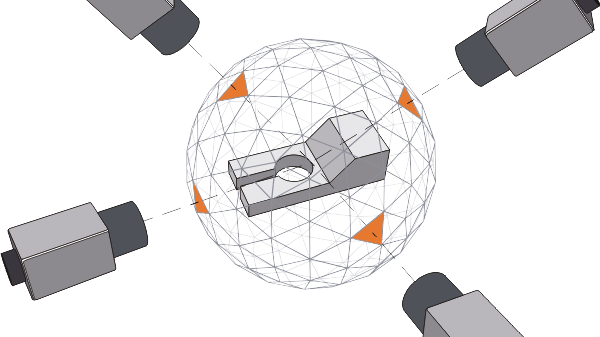

- Detect 6D poses of objects in 3D, e.g., for bin picking

- Precisely aligning parts, e.g., for further assembly processes

Very specific application examples are:

- Pick & Place of parts during assembly of electric components

- Precise detection of ripe crops for automated harvesting

- Bin picking

- Precisely aligning small parts for assembly in semiconductor industry

- Detecting box positions for de-palletizing in logistics industry

Read more about the technologies, you will find in our software products to help you with your position recognition applications:

Position recognition technologies

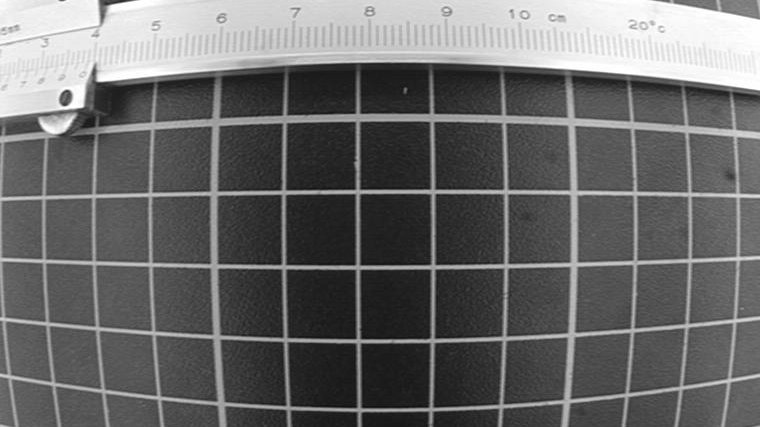

Position recognition 2D

Position recognition 3D

Read more about how machine vision could be helpful in your industry or take a look at our customers success stories to find specific examples of the applications.